A couple years ago, I wanted to fix the warped HSI chips I had, and there were already instructions about putting the chips in a stack in the oven. I really didn't want to go that route, it seemed like it would take a long time, and the lowest setting on my oven was 200 degrees.

I was thinking of alternate ways to heat the chips and was set on using hot water, but then realized how difficult it would be to manage the temperature, and the water would cool too quickly to make this an effective process.

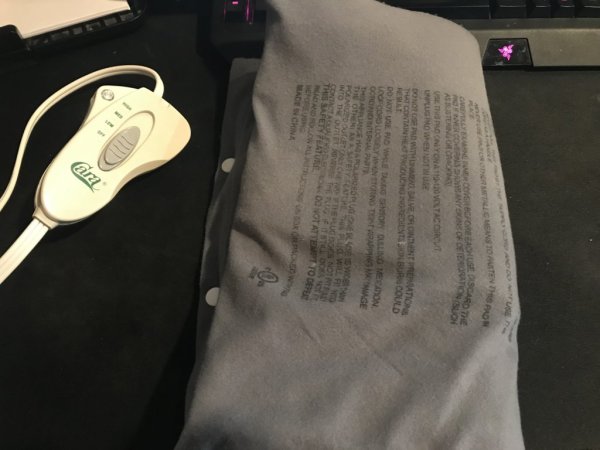

Then it dawned on me…a heating pad!

After much back and forth, I got a method for flattening chips that seems to work well.

I use a heating pad that generates a range of between 142-168 degrees. I wouldn't go much higher, or the chips may get too soft.

I work with 10 chips at a time, placing them in one layer, and arrange them to one side of the pad.

I fold over the pad, avoiding a sharp crease. Heat for 10 minutes, and I’ll gently put a small amount of pressure on top so that it doesn't flop open. You can also put the 11 spacers (more on that to come) on top to hold the pad closed.

Remove the chips and then using ceramic blanks, carefully align them and clamp in a hand clamp (very snugly but not SUPER tight). In the photo, I used 39mm spacers, but if you can source 43mm ceramic spacers, it’s highly recommended. The reason is that if the chips are not aligned PERFECTLY, there’s a chance that any overhang of the spacer will leave a mark on the clay chip. Having spacers larger than the clay chip would resolve this issue.

I can't stress enough how little clamp pressure is needed to get them flat. I use hand clamps, and I use just enough pressure that they stay in the clamp, Do NOT crank down on them, it will damage the soft, warm clay.

Put the clamped chip barrel to the side and let cool for 1-2 hours before unclamping.

Generally, this needs to be done only one time, but once in a while, a few stubborn chips may need a second round of heating and clamping.

Enjoy the flat chips!

I was thinking of alternate ways to heat the chips and was set on using hot water, but then realized how difficult it would be to manage the temperature, and the water would cool too quickly to make this an effective process.

Then it dawned on me…a heating pad!

After much back and forth, I got a method for flattening chips that seems to work well.

I use a heating pad that generates a range of between 142-168 degrees. I wouldn't go much higher, or the chips may get too soft.

I work with 10 chips at a time, placing them in one layer, and arrange them to one side of the pad.

I fold over the pad, avoiding a sharp crease. Heat for 10 minutes, and I’ll gently put a small amount of pressure on top so that it doesn't flop open. You can also put the 11 spacers (more on that to come) on top to hold the pad closed.

Remove the chips and then using ceramic blanks, carefully align them and clamp in a hand clamp (very snugly but not SUPER tight). In the photo, I used 39mm spacers, but if you can source 43mm ceramic spacers, it’s highly recommended. The reason is that if the chips are not aligned PERFECTLY, there’s a chance that any overhang of the spacer will leave a mark on the clay chip. Having spacers larger than the clay chip would resolve this issue.

I can't stress enough how little clamp pressure is needed to get them flat. I use hand clamps, and I use just enough pressure that they stay in the clamp, Do NOT crank down on them, it will damage the soft, warm clay.

Put the clamped chip barrel to the side and let cool for 1-2 hours before unclamping.

Generally, this needs to be done only one time, but once in a while, a few stubborn chips may need a second round of heating and clamping.

Enjoy the flat chips!

Last edited:

Upvote

0